Porcelain Insulator News

by Jack H. Tod

Reprinted from "INSULATORS - Crown Jewels of the Wire", August 1974, page 10

Preferably direct porcelain news item and questions directly to Jack H. Tod,

3427 N. 47th Place, Phoenix, Ariz. 85018. All mail will be answered if reply

stamp is enclosed, and the most newsworthy items and questions of general

interest will be published as space permits.

HOW MUCH DO YOU REALLY KNOW ABOUT PORCELAIN INSULATORS?

As a little diversion for the dog days, we've prepared the following quiz for

you. Really test yourself and try to answer all the questions before consulting

the answers following the quiz. If you get 20 of the 50 questions right, we know

you're a porcelain collector. Thirty right means you're a very studious

porcelain buff, and it you score 40 or more correct, maybe you should fill in as

editor of this column while I take a vacation.

PORCELAIN INSULATOR QUIZ

-

Rank the following companies first to last by when they started making

porcelain pin types:

__ Victor Insulators, Inc.

__ Hartford Faience Co.

__ Ohio

Brass Co.

__ Gladding Corp.

__ Pinco

__ Lapp

-

Ohio Brass Company's insulator plant is at Mansfield, Ohio.

__ True __

False

-

Guy strain insulators are designed for interlocking wire loops because

porcelain is approximately 16 times stronger in compression than it is in

tension.

__ True __ False

-

Which of the following companies still make pin types?

__ General Electric

Co. (Locke)

__ Lapp

__ Westinghouse

__ Thomas

__ Jerrery-Dewitt

__ Finlay

-

Line Post insulators are individually tested in each quadrant direction at

only 50% of the mechanical load rating.

__ True __ False

-

The industry standard for acceptance of any given production lot of pin

types is that 12-1/2% of the lot selected at random must all pass electrical

puncture test without exception.

__ True __ False

-

The only reason why one surface of the insulator is left unglazed is to

afford a firing surface which won't weld itself to the resting surface in the

kiln.

__ True __ False

-

Dry process pin types were popularly used in low voltage applications

because they were considerably cheaper to make than wet process insulators.

__

True __ False

-

Forestry insulators are usually made as split knobs because it is cheaper

to make them that way, and the crack between halves does no harm on phone lines.

__ True __ False

-

One reason why thru-hole "Mine Type" insulators were used in

mines on vertical pins was to allow moisture from above to run down through the

pin hole instead of onto the outer surface where it would short the wire.

__

True __ False

-

All porcelain pin types meant for use in power applications have a

conductor groove in the crown top.

__ True __ False

-

The firing temperature of electrical porcelain is:

__900 degrees F

__1480 degrees F

__1850 degrees F

__2200 degrees F

-

A well made glass insulator has approximately the same dielectric

strength as a well made porcelain.

__ True __ False

-

The tooling used to make porcelain insulators must allow for a firing

shrink of approximately 12%.

__ True __ False

-

Porcelain insulators are glazed to prevent the absorption of moisture by

the body of the insulator.

__ True __ False

-

Do porcelain pin types ever have drip points?

__ Yes __ No

-

Conventional suspension insulator disks with the cap cemented on top and

the pin cemented into the bottom place the porcelain in tension.

__ True __

False

-

Which of the following companies rarely marked their unipart pin type

insulators?

__ Pittsburg High Voltage

__ Hartford Faience Co.

__ General

Porcelain Co.

__ New Lexington High Voltage Porcelain Co.

-

Which of the following companies marked essentially every pin type they

made?

__ Locke

__ Thomas

__ Ohio Brass

-

Various porcelain insulator companies have collectively made less than

12,000 different types of insulators over the years.

__ True __ False

-

All porcelain pin types with two side grooves and without a top groove

are transposition insulators.

__ True __ False

-

Most current pin type power insulators are basically little different

from designs created over 50 years ago and indicate it's hard to improve on a

sound original design.

__ True __ False

-

Fogbowl and Fog Type insulators are used in areas of contamination even

though fog is never present there.

__ True __ False

-

Embossed (raised letters) markings are found on dry process porcelains

where the dies can be punched with the marking as with dies for making glass

insulators. There is one example of a true embossed marking on wet process pin

types. What marking in this?

____________________

-

Match up each of the following marking methods with the stage of

manufacturing process where the marking is applied to the insulator.

__ Embossed

(a) just before glazing dried insulator

__ Incuse (b) marking

incorporated in forming die

__ Underglaze (c) immediately after green trimming

__ Overglaze (d) after kiln firing & electrical test

__ Sandblast (e) last

step before kiln firing

-

Nail knobs and small solid knobs are occasionally found with black, brown

or blue glazes, and these were used to code special switching circuits.

__ True

__ False

-

The standard glaze during the early years of porcelain manufacture was

white; the Imperial and early Thomas insulator styles are rare to unknown in

brown.

__ True __ False

-

A closed-end guy strain insulator is one with a wire hole through each of

its ends.

__ True __ False

-

A "reversible" cleat or split knob is one where both the mating

halves are identical with each other.

__ True __ False

-

The term "ceramic" is an incorrect one for modern pin type

porcelain insulators.

__ True __ False

-

Fred Locke was the first one to make high-voltage porcelain insulators.

__ True __ False

-

Prior to the development of electrical porcelain wiring insulators in the

early 1890's, wooden insulators were used for surface wiring and led to many

fires.

__ True __ False

-

Several insulator manufactories burned to the ground, but which of the

following had the distinction of having burned to the ground twice?

__ Jeffery-Devitt,

Kenova, W. Va.

__ Lima Insulator Co., Lima, N.Y.

__ New Haven Porcelain Co., New

Haven, W. Va.

__ Imperial Porcelain Works, Trenton, N.J.

-

It is a slow and expensive process to make insulators by casting liquid

clay slip, and no company has ever based its main production on this method.

__

True __ False

-

Paraffin-resist methods of affording an unglazed

firing surface are

relatively modern, and any insulator with a firing surface made by carving,

sanding or fettling off the unwanted glaze can be assumed to have been made

before about the time of the first World War.

__ True __ False

-

Which of the following glaze colors is extremely hard to make on

porcelain and has never been used in any regular production of porcelain

insulators?

__ Blue

__ Green

__ Red

__ Yellow

-

White insulators are always much scarcer than brown ones and are

therefore worth more in all cases.

__ True __ False

-

There are many varieties of blue porcelain pin types, but all of these

have been made by only 3 companies.

__ True __ False

-

The modern "sky" glaze porcelains are made to a given

specification of the National Electrical Manufacturer's Assn. and are relatively

identical for each company.

__ True __ False

-

A number of porcelain insulator styles have been made to copy the various

amber glass insulator styles.

__ True __ False

-

Collectors do not want multi art pin types (two or more parts cemented

together), and they have little or no collector value.

__ True __ False

-

Low-voltage secondary distribution pin types are generally not

manufactured with "radio treated" tops because radio interference

problems usually don't occur on lines operating under about 6600 volts.

__ True

__ False

-

Collector value of porcelain pin types is determined mainly by the

insulator style (shape).

__ True __ False

-

Hewlett-type strain and suspension insulators lost their popularity

because they were less reliable than the modern styles of suspension insulators.

__ True __ False

-

Suspension insulators used in horizontal strings (the deadend position)

must be rated for higher voltage because the underside in completely wetted by

rain.

__ True __ False

-

Illinois Electric Porcelain sold insulators under "The Macomb

Line" throughout its life, and the M in the Triangle-M Illinois marking

stands for "Macomb".

__ True __ False

-

One U.S. pin type manufacturer was known for making many insulators to

customer specifications and sold a sizeable amount of its production to Canadian

companies and to various foreign countries. What manufacturer was this?

______________________

-

Johns-Manville made a number of different porcelain insulator styles,

some being marked "JOHNS-MANVILLE"

__ True __ False

-

Large insulators with flat metal base plates and top caps are used for

and referred to as "Switch & Bus" insulators.

__ True __ False

-

As compared with glass insulators, marking errors on porcelain pin types

are relatively few in number.

__ True __ False

PORCELAIN QUIZ ANSWERS

-

Ohio Brass (1907), Lapp (1916), Pinco (1920), Hartford (1925), Victor

Insulators Inc. (1935), Gladding (1963)

-

False, That's where the main company

is, but the insulator plant is at Barberton, a suburb of Akron, Ohio.

-

True.

-

None of them. The only companies still at it are I-T-E, Pinco, Chance,

McGraw-Edison, O-B and Gladding.

-

True, the theory being that any firing flaw which would break at full load

will break at 50% (so help me Hannah!).

-

False. Every single insulator is 100%

electrically tested and is rejected if it does not pass.

-

True.

-

True.

-

False. They are made that way so they can be installed on Lines already strung,

as in replacing broken insulators, and also so that new lines need not be

threaded through all insulators before tensioning.

-

True. Mine insulator pins were made fluted or in split form to assist in

the passage of water. Also when used an duplex insulators upside down under

crossarms. , they will not trap water which would freeze and break the

insulator.

-

False. Side-tie styles are commonly used for secondary

distribution circuits.

-

2200 degrees F.

-

True; the disadvantage of glass

insulators for many power applications is their relatively inferior mechanical

strength.

-

True.

-

False. Electrical porcelain is completely nonporous. The reason

for the glaze is to furnish a surface which is more readily cleaned by

rainwater, and also to provide a less objectionable color than the white body.

-

Yes, they all do. In porcelain nomenclature, any exposed edge or rim from

which water drips to a lover level is termed a drip point.

-

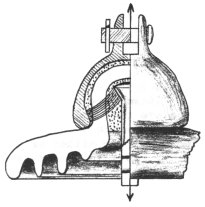

False. As shown in this sketch, proper design of the cap and pin pressure

surfaces places the porcelain in compression as it should be.

-

Pittsburg and

New Lexington.

-

Ohio Brass Co.

-

False. The number would exceed a million

different kinds. Just one company alone (Lapp) has issued over 300,000 drawings

for various porcelain insulator designs they have made to date.

-

False. Many power insulators have one or more grooves cut under the

tie-wire groove solely to create a longer electrical leakage path from tie wire

to pin.

-

True.

-

True. The name stemmed from the fact that flashovers on

contaminated insulators tended to be triggered when the fog rolled in, but

contamination is still a problem in areas which don't even have fog.

-

The

Ohio Dream Co. marking used up until 1940. Thereafter the marking is a pseudo

embossed marking made with a stamp after trimming, and this we term

"recess-embossed".

-

Embossed - b; Incuse - c; Underglaze - a; overglaze - e; Sandblast - d.

-

False. These were included in outdoor radio antenna kits sold by various

radio companies and mailorder houses, and which included a roll of antenna wire,

a couple of radio strain insulators, a lightning arrestor, etc. The dark glaze

colors made these items less conspicuous on the house.

-

True. On the other

hand, Fred Locke started out with a light brown glaze in 1898 and didn't develop

a white glaze until 1901. Most items with "Fred Locke" markings are

much scarcer in white than they are in brown.

-

True.

-

True.

-

False. It is technically correct, but the more

definitive term "porcelain" is used to differentiate from other

insulators made of steatite, alumina, etc.

-

False. He was preceded by

General Electric (Schenectady), Peru Elec. Mfg. Co., Imperial Porcelain Works

and Thomas. After only jobbing glass insulators for many years and porcelain

insulators for about three years, he built his own porcelain insulator plant in

1898. He was considered the father of the industry because his plant was built

exclusively for the manufacture of wet process high-voltage insulators.

-

True.

-

Lima Insulator Co. In 1908, rebuilt and bought out by Locke

Insulator Mfg. Co. in 1910, only to burn down again in 1919 (subsequently

rebuilt and owned by Pinco). The other plants listed only burned to the ground

one time each. The Kenova plant was never rebuilt.

-

False. Jeffery-Dewitt

built its plant for the production of suspension insulators by casting and made

nearly all its insulator types by casting, and this competitive disadvantage was

a factor in the company's demise in the 1930's.

-

True.

-

Red, which fires to black at normal firing temperature. Ohio Brass made a

small lot with "great difficulty" for a fire alarm company. They ended

up firing them in the lab kiln and said, "never, never, never again."

-

False. This is true for most relatively modern items, but many early items

were normally made in white, and brown ones of these are rare and desirably

varieties.

-

False. All companies since the early 1900's have made blue ones

at one time or another either as stock items or on special order.

-

True. The polar coordinates on the Munsell "gray" color chart

are specified for hue and intensity, and it is up to each manufacture to brew

his own glaze slip to match this color specification within a given tolerance.

-

False. It's the other way around.

-

False. The modern, large multiparts

have little collector appeal, but older and more unusual styles and colors are

desirable collector items, especially the smaller varieties.

-

True

-

False.

Value is based on a combination of insulator style, color and rarity of marking.

Each factor in itself can make an otherwise worthless item a good item, just as

is with glass insulators. The object is to find an unusual style in a good color

and with a rare marking, and then you have a "super goody".

-

False. They were possibly even more reliable, but, their complicated

assembly hardware did not lead itself to easy replacement of faulty units in

strings on activated transmission lines.

-

False. In fact, on some lines the

ones in the vertical strings can fail first due to underside contamination

deposits not being washed away by rainwater.

-

True.

-

Pittsburg High Voltage Insulator Co.

-

False. J-M never had a

porcelain plant. They cataloged and sold a very large line of porcelains, most

of which were Thomas insulators, but never made then. Pittsburg, New Lexington

and possible others made insulators for J-M and marked many of these with the

J-M name for the customer.

-

True.

-

True.

|